Technical Introduction to the UPI 1000TA™ Generator

Description

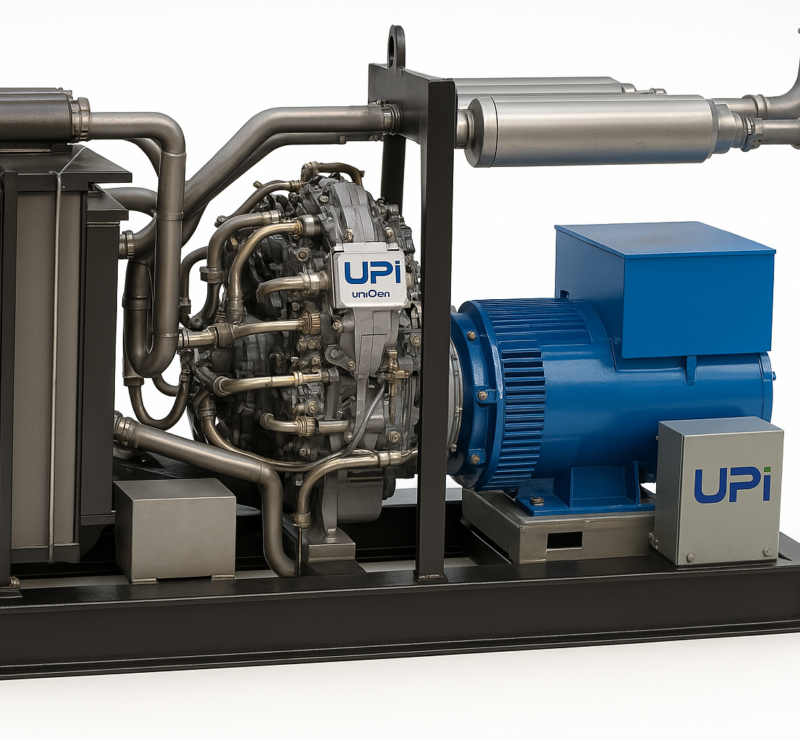

UniGen Power, Inc. introduces the UPI 1000TA™ – the world’s smallest, lightest and quietest one megawatt power generation system. Developed specifically for gaseous fuels. This liquid cooled, radial engine delivers outstanding electrical efficiency of over 46% and emissions compliance at low operating costs. With standard enclosure and sound attenuation, advanced monitoring and controls, fuel agility, and optional mobility package, the UPI 1000TA™ sets a new standard in mobile and distributed power generation.

COMPONENTS

Advanced Radial Configuration 1000TA™ Engine

The proprietary design 1000TA™ has been engineered for robust industrial performance utilizing advanced combustion technology and state-of-the-art alloys, coatings, and tolerances.

The power plant delivers high-load capacity, extended maintenance intervals, and long service life while retaining all the advantages inherent in its radial design: lightweight, high horsepower, low internal friction, and excellent operating efficiency, liquid-cooled, turbocharged, with fewer parts and bearings, the 1000TA™’s unique combination of features enables the UPI 1000TA™ to deliver unprecedented mobility, durability, fuel efficiency, and emissions compliance.

UPI Proprietary Electronic Control Module

Microprocessor-based diagnostic, monitoring and control system integrates engine and alternator controls in a single system employing CAN bus technology. Operator-friendly instrumentation is displayed on-board through 17” color touch screen monitor or on remote computer via Ethernet connection or proprietary software. Controls are suitable for both parallel and nonparallel applications, with other gensets and with utility service. Paralleled gensets may be accessed through a single interface. The system is designed for EMC compliance and constructed to meet the most rugged duty cycles for gensets.

Full Turn-Key Functionality

The UPI 1000TA™ is spec’d, quoted and shipped as a fully operational unit for most environments and applications. Optional equipment may be ordered to provide additional functionality for specific uses.

Worldwide Voltages

Supports all standard voltages worldwide.

Low Operating Cost

- The fuel cost of natural gas is significantly less than diesel.

- Maintenance cost minimized by simplified fuel and intake systems, advanced filtration, and reduced fluid quantities.

- Overhaul cost and time reduced due to extended service intervals and unique engine design permitting improved access to major engine components and independent cylinder service.

Status & Diagnostics

Comprehensive monitoring of engine and generator performance with predictive maintenance diagnostics. Worldwide network access available.

Fuel Agility

- Natural gas (pipeline, CNG, LNG)

- Biogas, landfill gas, flare gas

- LP gas (propane & butane)

- Ethanol

- Hydrogen

Emissions Compliance

Inherently lower and more easily controlled emissions than competitive diesel engines. Meets all applicable current and scheduled EPA, CARB and EU regulations for spark-ignition engines.

Superior Mobility

Lightweight and compact, the UPI 1000TA™ is the smallest and lightest 1MW power source available in its class. At one-third the size and one-fifth the weight of comparable diesel gensets, the 1000TA™ easily transports to remote sites or disaster relief locations.

Full Authority Remote Control

Full control of engine and generator functions at a remote computer via Ethernet connection and proprietary software.

Engine:UPI 1000TA™

- 9-cylinder, radial configuration, liquid cooled, 1155kW, constant 2300 rpm, twin turbocharged with aftercoolers

Fuel System

- Low pressure fuel system requires only 2.0 to 5.0 PSI

- Single fuel calibration curve (methane or propane)

- Gas train, gas pressure interlock, air cleaner

Charging and Start System

- 100-amp alternator for battery charging and controller system power.

- Twin 24V starting motors

- Lead acid batteries with racks and easy access provision

Lubrication System

- Full flow oil filtering, 30-gallon reservoir, synthetic oil, electric pre-lube pump, multi-stage oil pressure and scavenging pump, shut down scavenging pump, positive gearbox lubrication, low level oil detection, oil cooler, on-demand piston cooling system

Cooling System

- High volume liquid cooled, dual circuit thermal management system

- Heavy duty automated motor and pump system

Exhaust System

- Fully isolated replaceable bed catalyst and integrated residential grade muffler

- Complete stainless-steel piping and fittings.

Parallel Enabled

- Allows parallel operation of multiple gensets. Provides paralleling data, functions and protection, also frequency synchronization and voltage matching.

Electronic Control Module

- Integrated spark timing control, turbocharger control, speed governing, cylinder knock control, time-stamped full diagnostics reporting system

- Complete engine data display capability

- Genset and engine monitoring and protection including emergency stop, fail to start shut down, permissive start / fuel presence shut down, engine vitals monitoring

- Complete alternator protection and data display

- Complete logs for operational data, including start attempts, starts, running hours and kW hours

Enclosed Unit

- Protective weather enclosure with sound attenuation provides maximum 55 to 65 dBA @ 6 meters.

Alternator

- Three phase, 4 pole, continuous duty, class H insulation, auxiliary wound, IP 23, synchronous generator